Electro-mechanical assembly is a pivotal process in modern manufacturing that integrates electrical and mechanical components into cohesive systems. This assembly plays a crucial role in creating sophisticated products that require precise coordination between electronic and mechanical parts. As industries strive for efficiency and innovation, the demand for electro-mechanical assemblies has surged, driven by advancements in technology and the need for high-quality, reliable systems. This introduction outlines the significance of electro-mechanical assembly in various sectors, emphasizing its impact on productivity, reliability, and the overall success of manufacturing operations.

Overview Of Electro-Mechanical Assembly

Electro-mechanical assembly involves the integration of electronic and mechanical systems to create functional products. This process encompasses a wide range of activities, from component sourcing and assembly to testing and quality assurance. The assembly often requires skilled technicians who can handle intricate components, ensuring that every part functions correctly within the system. The efficiency of electro-mechanical assembly contributes significantly to the overall production timeline and cost-effectiveness. By combining advanced manufacturing techniques with skilled labor, businesses can produce high-quality products that meet market demands, thereby enhancing competitiveness in today's fast-paced industrial landscape.

Applications Of Electro-Mechanical Assembly

Electro-mechanical assembly has diverse applications across various industries, making it essential in modern manufacturing. Here are some key applications:

- Automotive Industry: Used in the assembly of control systems, sensors, and actuators, ensuring vehicle performance and safety.

- Consumer Electronics: Found in devices like smartphones and appliances, integrating circuits and mechanical parts for functionality.

- Medical Devices: Critical in manufacturing medical equipment, ensuring precision and reliability in life-saving technologies.

- Industrial Automation: Facilitates the creation of robotics and machinery, enhancing production efficiency and safety.

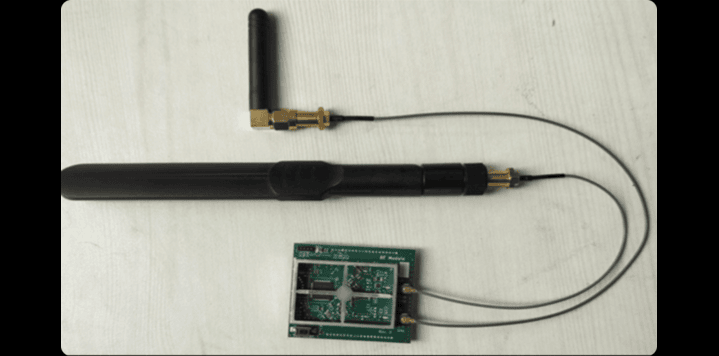

- Telecommunications: Essential in assembling communication devices, ensuring connectivity and data transmission reliability.

Quality Control In Electro-Mechanical Assembly

Quality control is vital in electro-mechanical assembly to ensure that products meet stringent performance and safety standards. Implementing rigorous quality assurance processes involves multiple stages, including component inspection, assembly checks, and final product testing. Techniques such as Automated Optical Inspection (AOI) and Functional Testing are commonly employed to identify defects early in the assembly process. Maintaining high-quality standards reduces the risk of product failures, enhances customer satisfaction, and strengthens brand reputation. As manufacturers increasingly prioritize quality, investing in advanced quality control methods has become essential for successful electro-mechanical assembly operations.

Future Trends In Electro-Mechanical Assembly

The future of electro-mechanical assembly is poised for transformation, driven by technological advancements and evolving industry demands. Automation and robotics are set to play a significant role, streamlining assembly processes and increasing efficiency. The integration of Internet of Things (IoT) technologies will enable real-time monitoring and data analysis, enhancing decision-making and predictive maintenance. Furthermore, advancements in materials science may lead to lighter, more durable components that improve overall product performance. As industries adapt to these changes, the electro-mechanical assembly sector will continue to innovate, focusing on sustainability and the development of smart manufacturing solutions.

Components Of Electro-Mechanical Assembly

Electro-mechanical assembly consists of various components that work together to create functional systems. Key components include:

- Printed Circuit Boards (PCBs): Provide the electrical pathways for components.

- Connectors: Ensure reliable electrical connections between parts.

- Actuators: Convert electrical energy into mechanical motion.

- Sensors: Detect changes in the environment and provide feedback.

- Cables and Wiring: Facilitate communication and power distribution.

Each component plays a critical role in ensuring the overall functionality and reliability of the assembly.

Benefits Of Electro-Mechanical Assembly

The benefits of electro-mechanical assembly are significant and can impact a manufacturer’s efficiency and profitability. Here are some key advantages:

- Increased Efficiency: Streamlined processes lead to faster production times and reduced costs.

- Enhanced Product Quality: Rigorous quality control measures minimize defects and ensure reliability.

- Design Flexibility: Allows for the integration of various components, enabling custom solutions for specific needs.

- Improved Scalability: Facilitates the production of large volumes without sacrificing quality.

- Reduced Time to Market: Efficient assembly processes enable quicker delivery of products to customers.

These benefits make electro-mechanical assembly an attractive option for manufacturers aiming to enhance their competitive edge.

Choosing An Electro-Mechanical Assembly Partner

Selecting the right electro-mechanical assembly partner is crucial for achieving manufacturing success. Factors to consider include the partner’s experience and expertise in the field, particularly in areas like custom sheet metal fabrication, their commitment to quality assurance, and their ability to adapt to changing project requirements. Communication is essential; a partner should be responsive and transparent throughout the assembly process. Additionally, evaluating their technological capabilities and production capacity, including their proficiency in custom sheet metal fabrication, can provide insights into their ability to meet deadlines and scale production as needed. A strategic partnership can significantly enhance the efficiency and quality of electro-mechanical assembly projects.

Conclusion

Electro-mechanical assembly plays a vital role in modern manufacturing, contributing to the production of reliable, high-quality products across various industries. The integration of electronic and mechanical components is essential for developing sophisticated systems that meet market demands. As technology evolves, the future of electro-mechanical assembly will likely see increased automation, improved quality control, and innovative applications. Manufacturers must prioritize choosing the right partners and embracing trends to remain competitive. By leveraging the benefits of electro-mechanical assembly, businesses can enhance their operations and drive success in the ever-evolving manufacturing landscape.

The post The Role Of Electro-Mechanical Assembly In Modern Manufacturing appeared first on New York Tech Media.

© 2025 Benzinga.com. Benzinga does not provide investment advice. All rights reserved.

Trade confidently with insights and alerts from analyst ratings, free reports and breaking news that affects the stocks you care about.