Like other common mechanical equipment, diesel generators require regular maintenance and care. The following 10 tips can help you extend the lifespan of your diesel generator and ensure smooth operation.

1. Routine General Inspections

During operation, potential leaks that could lead to hazardous incidents need to be monitored, including the exhaust system, fuel system, DC electrical system, and AC generator. Diesel generators produce vibrations during operation, which over time could cause bolts or other parts of the unit to loosen or even fall off. Regular inspections are necessary to check for any looseness or detachment of parts.

2. Check the Lubrication System

The lubrication system of a diesel generator is crucial. It lubricates, cools, and cleans the moving parts of the generator while also sealing certain components to prevent rust. Before starting the engine, always check the engine oil level using the dipstick. The oil level should be as close as possible to the full mark. The engine oil and filter need to be replaced regularly. A standard maintenance interval for oil changes is every 500 operating hours, but specific conditions may require shorter or longer intervals. When adding or changing oil, always try to use the same brand and quality of oil. It's best to purchase lubricants that meet OEM specifications.

3. Check the Cooling System

When the equipment is not running (engine is cooling down), periodically check the coolant level. When the engine is cool, remove the radiator cap and inspect whether the radiator is full. Coolant may be water, antifreeze, or other additives, or a mixture of these. Daily checks should include ensuring there are no obstructions on the radiator and removing dirt or debris to avoid damaging the radiator.

4. Check the Fuel System

Diesel fuel can become contaminated and corroded within a year, so it’s strongly recommended to run the generator regularly to use up the stored fuel before it degrades. Due to the accumulation and condensation of water vapor in the fuel tank, the fuel filter should be drained at specified intervals. If fuel has not been used or replaced within three to six months, regular testing and fuel polishing may be needed. Preventive maintenance should include a thorough inspection of the fuel system, coolant levels, oil levels, and the starting system. Regular checks should be made for leaks, holes, cracks, dirt, and debris in the turbocharged air cooler pipes and hoses, which may clog the radiator fins or cause loose connections. During maintenance, fuel filters and water separators should be replaced if necessary.

5. Check the Battery

Insufficient or undercharged starting batteries are common causes of backup power system failure. Batteries must be kept fully charged and well-maintained to avoid startup failures. Regular testing and inspection of the battery's current condition are essential. The battery terminals should be kept clean, and the specific gravity and electrolyte levels should be checked regularly to ensure they are not oxidized or loose.

6. Regular Engine Exercise

Regular operation of the engine helps keep the components lubricated, prevents electrical contacts from oxidizing, exhausts fuel before it degrades, and aids in reliable engine starting. It's recommended to run the engine for at least 30 minutes each month, with a load of no less than one-third of the rated nameplate value.

7. Check the Exhaust System

Any leaks in the exhaust system, typically occurring at joints, welds, and gaskets, should be repaired immediately by qualified technicians. Always ensure that your equipment is maintained, especially within 24 hours before using the generator. For backup generators, service is required after an average of 150 hours of use. However, if the generator is used more frequently, service intervals will decrease and become more regular.

8. Check the Wiring

Inspect the entire generator’s electrical wiring for any loose or detached connections, including inside the control panel, load connections, wiring to the engine, and emergency stop devices.

9. Keep the Diesel Generator Clean

Diesel generators should be kept clean. When the engine is clean, oil drips and other issues are easier to spot and address. Visual inspections can help ensure that hoses and belts are in good condition. Regular checks prevent pests like hornets and other nuisances from nesting in your equipment. The more frequently you use and rely on your generator, the more important it is to maintain it.

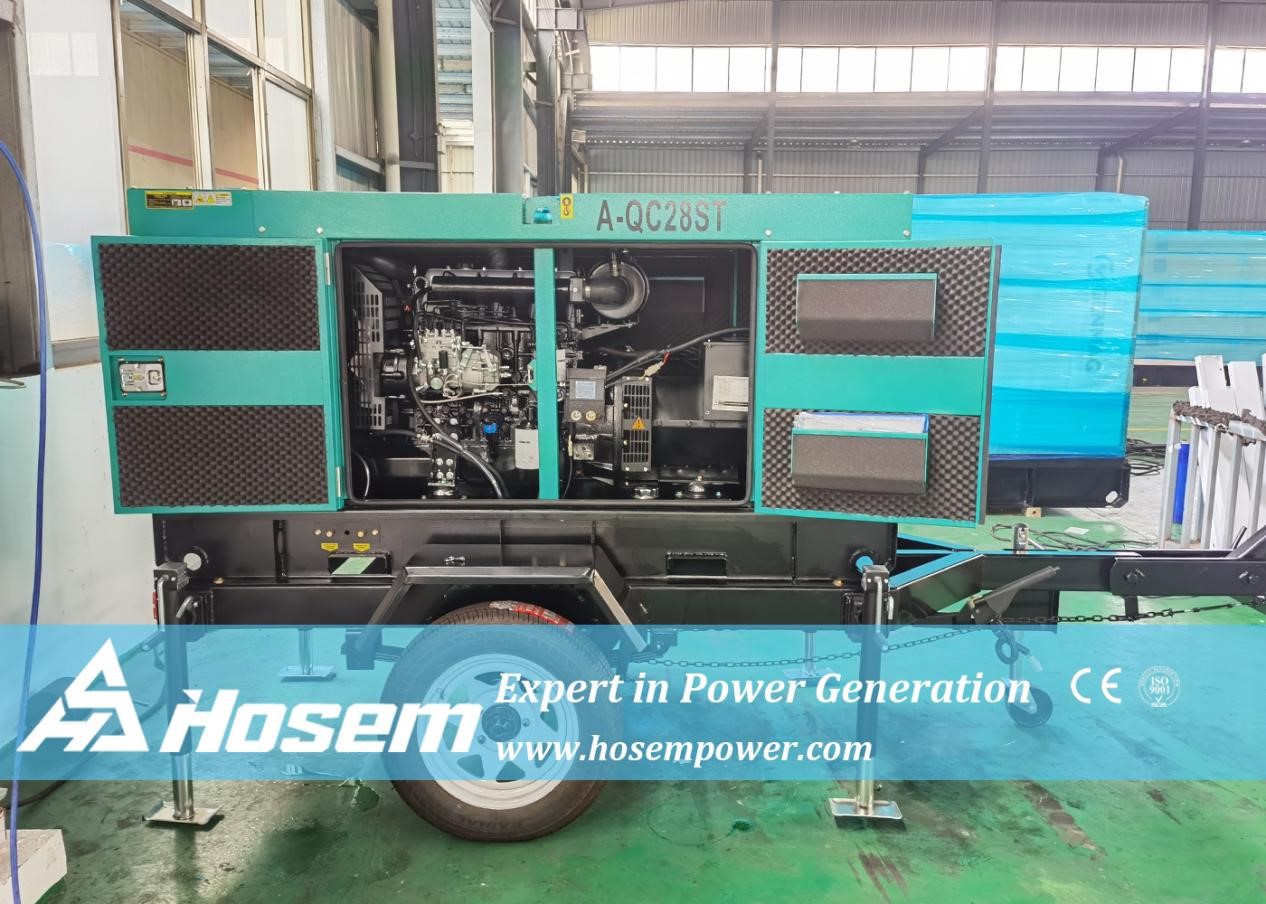

If you’re looking for the best diesel generator, Hosem Power is a professional diesel generator manufacturer offering a wide range of products, from standard fixed diesel generators to mobile trailer generators and silent type generators, light tower. Brands include like Cummins, Perkins, Deutz, Isuzu, Yanmar, Kubota, Weichai, Yuchai, SDEC etc. Whatever type and brands of generator you choose, we can provide you with the perfect diesel generator to suit your needs.

Contact us

Whatsapp: +8613205904365

Email: industrialgeneratorset@gmail.com

The post 9 Essential Tips for Properly Maintaining Diesel Generators for Smooth Operation appeared first on New York Tech Media.

© 2025 Benzinga.com. Benzinga does not provide investment advice. All rights reserved.

Trade confidently with insights and alerts from analyst ratings, free reports and breaking news that affects the stocks you care about.